![]() 5 minute read

5 minute read

Are you buying new clothes? Having weekly Sunday-Laundry instead of Sunday-Funday? Forget about it! Soon the world will welcome fashion wearables performing self-cleaning and transforming style and color. At the same time, industry will become a closed loop production with emphasis on reuse and recycle. Let’s explore the future where science, technology, and fashion intersects.

End of laundry

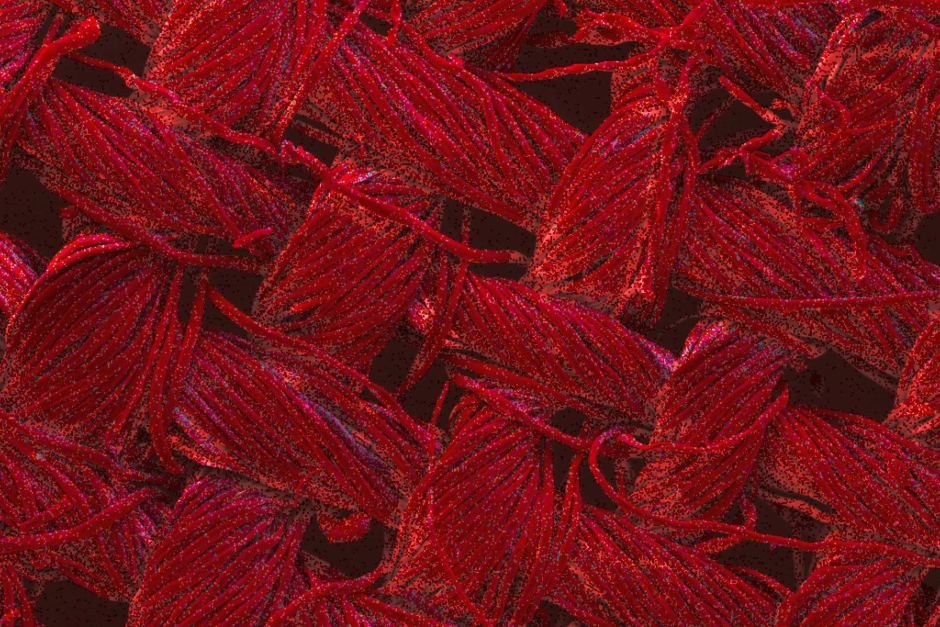

Haven’t we all dreamed of the moment when fabric could clean itself? We are glad to inform you that the secret of self-cleaning fabric is solved by copper. It is thought to be one of the most sustainable solutions for the textiles industry. Researchers from RMIT University have developed new nanostructure that can degrade organic matter when exposed to light. On the sunlight, the tiny metal particles release bursts of energy that cleans textile in less than six minutes.[nbsp]To grow nanostructure directly on the fabric, it is enough to dip textile in a few solutions.[nbsp]

Close-up of the nanostructures, magnified 150,000 times. Photo: RMIT University

Dr. Ramanathan, a postdoctoral fellow at RMIT, says: “Basically what we do is take a simple cotton textile, we have a few different new methodologies to grow nanostructures directly on them, and then once these structures are formed we can just shine a light on them.” Next step is to upgrade technology to fight against offensive odors.

Eternity of

fresh bedding

Another example is 29 Linen project currently on Kickstarter. No nano-technologies, but using beneficial features of copper. 29 Linen offer copper infused bedding that discharges bacteria and keeps bed fresh.

These inventions are important for the world for several significant reasons. To begin with, this technology would save water and electricity used for laundry opening the doors to sustainable textiles. Moreover, self-cleaning tech is an outstanding opportunity for developing countries to cope lack of utilities, resources, and abundance of bacterias. What is more, copper and silver used for this nanostructure are relatively cheap. This technology has a lot more to offer than apparel – interior textile which is so challenging to clean. Opportunities are endless as well as benefits.

Forget about wearables,

It is Smart fashion

Today all the digital services are available in the form of wearables – wristbands, watches, rings, etc. According to Gartner, smart garments is one of the largest and fastest growing sectors. However, this trend might not be around for long. Apparel is preparing to infuse with technology taking implementing sensors and substituting smart wearables. Back in 2014, Ralph Lauren has launched a PoloTech shirt outfitted with multiple sensors. The shirt transmits data with wearer’s heart rate, stress level, and energy output, straight to an app. For Olympians and sports teams such sensors are a complete breakthrough. Several sports brands including Hexoskin, Athos, andPhysiclo, embed sensors to their clothes to monitor and thus enhance athletes performance. A combination of copper nanotech and smart sensors will make clothes to be fresh, clean, and smart for years. We will see the fusion of different industries in the textiles industry. “Smart fashions frequently use technologies that are better known in sectors normally not associated with fashion, for example, architecture, the automobile industry, aviation and the medical industry,” said Michael Jänecke, Brand Manager, Techtextil and Texprocess, Messe Frankfurt.

Nordics Textile Commitment

There is still overconsumption issue in the textile market before moving to the digitalization of the industry. The consumption of new textiles in the Nordic region alone amounts to 350,000 tons per year and is expected to increase to over 450,000 tons by 2020. This trend is not a sustainable one and needs an immediate intervention. For example, in Swedish Green party is nudging people to make better choices. One of the paths is to pay people for fixing their belongings instead of buying new. Sweden has granted a tax break for repairment industry lowering the VAT from 25% to 12%. This technique has proven to be more than successful as it has created new working places as well.

Fashion is the second most polluting industry in the world after oil. The development of circular economy for textiles is vital for sustainable future. “Closing the loop” of textile production is a mission of Nordic countries. A social enterprise Circle Economy has launched the Circle Textiles program. The program includes raising awareness via media, events, and workshops to transform the[nbsp]industry into zero-waste and transparent one. Also, there is a Nordic Waste Group created to tackle the issue. “The idea has been to reduce the environmental impact of textile consumption in the Region by increasing reuse and recycling,” says Sanna Due-Sjöström, chair of the Nordic Waste Group. “Our studies indicate that we could create more than 4,000 jobs in the Region related to the collection, sorting, reuse and recycling of used textiles and via expanding business models like leasing, repair and sharing of textile products.”