![]() 4 minute read

4 minute read

There is no person, who has not though how to implement 3D printer whether for manufacture or for home usage. The fact of popularization new technology is undoubtful and we foresee the way it will be a part of EcoCity.

Printed cities

are reality

3D printing has an impact to almost every sphere of human being life from manufacture till Health Care. What is more, 3D printing adds value and possibilities into sustainable development of the world. The problem of provision of living space in urbanization period can be solved by implementation latest additive manufacture.

An innovative Smart Bricks are lego-like construction elements made out of high-strength concrete. Using a lego-like ground plate as a base of the house, bricks are installed one element on the top of another via robot. This is how the walls are set up – just like a lego construction. The finishing layers cover the infrastructure elements like pipes and cables. The bricks have thermal properties to save up to 60% of energy costs for a building. Isn’t that an engineers’ dream?

As 3D printers can produce the materials for houses, they also are used as a building machine. Chinese WinSun using four 10m x 6.6m 3D printers rises 10 detached single-storey houses a day with the mixture of cement and construction waste as a printing material. The building of the houses is noiseless, zero-carbon, and zero-waste. And in case if the energy supply is provided by solar power, we get an excellent formula of eco-building. All materials are reusable and power is renewable. Moreover, the magnificent part of such technology is the price. The average cost of 3D printed [nbsp]single-storey house is $5 000. For now, it is the fastest and cheapest way of building. The future for this technology is bright: “Our printers can be used to build skyscrapers in the future. At the moment, however, Chinese construction regulations do not allow multi-storey 3D-printed houses”, says WinSun chief executive Ma Yihere.

Engineers for

manufacture

reinvention

“Honey, print me a red cabriolet!” The sentence must sound funny today, but not in 50 years, when 3D printers are usual home tech. The printing material will be reusable and the only thing you will need to buy is a design idea. 3D printers will trigger an opening of a new cloud-based market of blueprints with software and hardware specifications. Alternatively, there are already open-source portals offering the prototypes of the products. The prototypes are highly customized and limited only with designers imagination. Already today, NASA engineers use 3D printers to build a next-generation rover to support humans exploring other worlds, such as asteroids and, eventually, Mars.

Additive manufacture, or manufacture using 3D printers, in other words, is a revolutionizing sustainable solution. As it was described in the previous article, How one question changes the fundament of manufacture, the industries to turn new technologies looking for cost and resource efficient solutions. The only obstacle stopping the manufacture to fully adopt the 3D printing technology was a production time. Thankfully, Joseph M. DeSimone, an innovative polymer chemist and a co-founder Carbon3D, has presented a breakthrough in the area of additive manufacture. He reinvented “2D printing”, as he names it, into 3D one using the prosperities of oxygen and the light. Joe’s invention works 25 to 100 times faster than traditional 3D printers, which is a game changer for modern technologies. In addition to its production speed, the printer opens up the opportunity for heat generation.

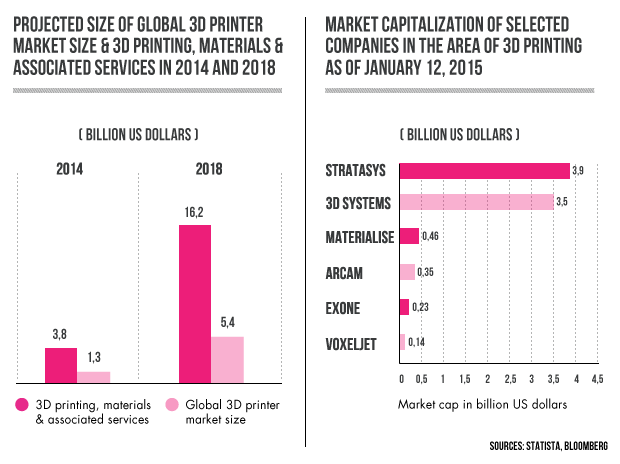

3D printer impact for global development will grow together with its market size. According to Bloomberg, market size of global market for 3D printing, materials [&] associated services and global 3D printer market size is expected to enlarge with 77% and 76% respectively in 2018 comparing to 2014. Bloomberg’s prediction only affirms if to look at Statista’s market capitalization of selected companies in the area of 3D printing as of January 2015.