![]() 5 minute read

5 minute read

As markets become global, the supply chain model of multinationals changes drastically. Increased use big-data to analyze and predict is the need of the hour. Furthermore, increased demand for efficient delivery infrastructure has forced companies to innovate their logistics capabilities. The future of SCM is one where the creativity of human brain infuses with the efficiency of machines.

Data as raw material

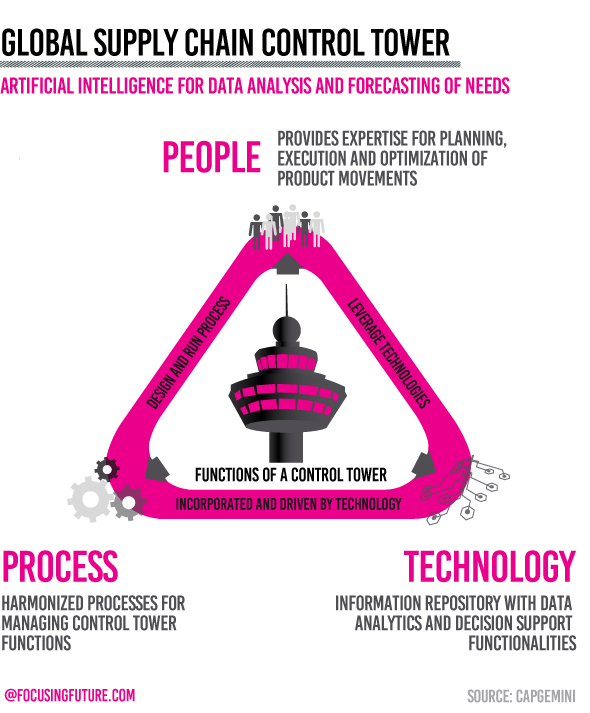

With time, companies have realized the need for an epicenter of information which can function as an effective projection mechanism for supply chain orchestration. Capgemini calls such hub a ‘global supply chain control tower’. This tower will combine inputs from the organization, understand available technology and use it to enhance procuresses to capture and use supply chain data in line with the strategic objectives of the company. It would help companies shape the planning and routing of products and raw materials, keeping a check on cash inflows and outflows. The tower can also forecast possibilities using trends recognized in the data. All this information would help managers to make informed decisions and ensure a smooth supply chain.

Many companies are already moving on this path. IBM and Watson’s supply chain cognitive software intelligently combines and manages all steps of supply chain and ensures its smooth flow. ClearMetal, using advanced analytics on big-data improves the efficiency and profitability of freight traffic of companies. Using a dynamic software, they are able to predict vendor and carrier behaviors reducing the chances of buffer or misjudged inventory stocks. They also help their clients by managing labor scheduling, ensuring smoothness in the work process. Similarly, Resilinc, a cloud provider of supply chain resilience solutions, is helping General Motors geocode their supplier’s plants and logistics. This helps GM to better recognize their suppliers: their availability, backup alternative supply options, etc.

This epicenter would be very useful in ensuring the different legs of SCM. It would prepare companies for potential disasters, improve their ability of manufacturing and warehousing, and will make sure that the final product is easily deliverable to a potential customer. These measures would make SCM efficient, productive and indeed more environmentally friendly.

From efficient

warehousing to

autonomous delivery

In SCM the changes are everywhere from local to global levels, and management of warehouse can be addressed as “micro-SCM”. Increased pressure from e-commerce makes warehouse management a strenuous routine leading to high labor costs. To tackle this, companies are investing into robotic solutions. According to a survey by ARC Advisory group, labor management and Warehouse management systems are the most prioritized investments of executives. 15% of the surveyed executives chose procurement of autonomous mobile robots as a priority. Similarly, Tractica, predicts that the demand for warehouse robots will increase to 620,000 units annually by 2021 amounting to a global market value of $22.4 billion.

While the use of robots for mechanical work is already a reality, advancement in software has led to more intelligent robots. The future, according to Mark Silliman, CEO of Bold Robotics LLC is mass customization of the robots. Intelligence software that learns and performs in a dynamic environment is the need of the hour. ‘Collaborative robots’ used in Ford’s factory in Germany, for example, have helped increase the efficiency of production while helping improve the safety of the workers. Similarly, Magazino’s perception-controlled mobile robots can help pre-packing merchandise, preparing the warehouse for the next working day.

The timely delivery of a product is an important part of the customer experience. The future of delivery will follow the same route as warehousing: infusion with robotics. Autonomous transport systems will be more fuel efficient which is big companies such as Apple, Google, and all the major car companies are investing in the technology. Amazon Prime Air has already made a delivery through drones. More recently, they have been awarded a patent to use magnets, parachutes or spring coils to guide the drops. Similarly, Mercedes-Benz has pledged to invest €500 million in designing electrical vans that can carry numerous autonomous delivery drones. While the technology for autonomously driven trucks is being improved rapidly, companies like Rolls Royce are going a step further by planning to launch autonomous cargo ships by 2030.

Collaborative robots or ‘machine learning’ will not simply replace workers. Such technology is designed to work along humans to increase the efficiency and precision of the process. On the other hand, autonomous intelligence would only replace workers in tasks that are either dangerous to them or make them prone to errors. On its own, the influx of robotics in supply chain management will introduce a new era of jobs and make work environment a lot safer. Furthermore, it would save workers from monotonous giving them more space to be creative and make the most use of their potential.

#supply chain management #control tower #warehouse management #automation #robotization #big data #future trends